Which Packaging Method is Best

The best packaging method depends on your product, budget, sustainability goals, and shipping requirements. Here are some common packaging methods and their best use cases:

1. Corrugated Boxes (Cardboard Boxes)

✅ Best for: Shipping, e-commerce, retail, fragile items.✔ Pros: Strong, lightweight, customizable, recyclable.✖ Cons: Not waterproof, can be bulky.

2. Poly Mailers (Plastic Envelopes)

✅ Best for: Clothing, soft goods, lightweight items.✔ Pros: Lightweight, water-resistant, cost-effective.✖ Cons: Not eco-friendly (unless biodegradable), less protection.

3. Bubble Mailers (Padded Envelopes)

✅ Best for: Small electronics, books, fragile-but-light items.✔ Pros: Extra cushioning, lightweight.✖ Cons: Plastic waste, not for heavy items.

4. Rigid Boxes (Luxury Packaging)

✅ Best for: High-end products (cosmetics, tech, jewelry).✔ Pros: Premium look, sturdy, protects well.✖ Cons: Expensive, heavier for shipping.

5. Shrink Wrap

✅ Best for: Bundling products, securing pallets.✔ Pros: Tamper-proof, weather-resistant.✖ Cons: Plastic waste, requires heat application.

6. Vacuum Packaging

✅ Best for: Food, medical supplies, reducing bulk.✔ Pros: Extends shelf life, compact.✖ Cons: Requires special machinery.

7. Glass or Plastic Jars/Bottles

✅ Best for: Liquids, food, cosmetics.✔ Pros: Reusable, good for branding.✖ Cons: Heavy, breakable (glass).

8. Sustainable Packaging (Biodegradable/Compostable)

✅ Best for: Eco-friendly brands.✔ Pros: Reduces environmental impact.✖ Cons: Often more expensive.

Which is Best for You?

E-commerce shipping? → Corrugated boxes or poly mailers.

Fragile items? → Double-wall cardboard + bubble wrap.

Luxury products? → Rigid boxes with foam inserts.

Eco-friendly? → Recycled cardboard or compostable mailers.

Would you like recommendations based on a specific product?

How does an automat packaging machine work?

An automatic packaging machine is designed to efficiently pack products into containers, wrappers, or bags with minimal human intervention. These machines are widely used in industries like food, pharmaceuticals, cosmetics, and logistics. Here’s a general breakdown of how they work:

1. Product Feeding

Products are fed into the machine either manually, via a conveyor belt, or through an automated system (e.g., robotic arms, vibratory feeders, or hoppers).

For granular or liquid products (like chips, powders, or beverages), a filling system measures the correct quantity.

2. Packaging Material Handling

The machine loads packaging material, which could be:

Pre-made bags/pouches (for snacks, coffee, etc.)

Roll-fed film (for flow wrap, shrink wrap, or vacuum sealing)

Rigid containers (bottles, jars, or boxes)

3. Forming & Filling (if applicable)

For flexible packaging (pouches/bags):

The film is unwound from a roll and shaped into a bag.

The product is dispensed into the formed pouch.

For pre-made containers (bottles/cans):

The containers are automatically positioned, filled, and sealed.

4. Sealing & Closing

Heat sealing, adhesive sealing, or ultrasonic welding is used for plastic films.

Lids, caps, or induction seals are applied for rigid packaging.

5. Labeling & Coding (Optional)

Labels, barcodes, expiry dates, or batch numbers are printed and applied.

6. Quality Control (Optional)

Some machines include weight checkers, metal detectors, or vision systems to ensure proper sealing and labeling.

7. Discharge & Sorting

The finished packages are ejected onto a conveyor or sorted into boxes for shipping.

Types of Automatic Packaging Machines

Vertical Form-Fill-Seal (VFFS) – Creates bags from a roll and fills them (e.g., chips, coffee).

Horizontal Form-Fill-Seal (HFFS) – Used for items like candy bars or frozen foods.

Bottle Fillers & Cappers – For liquids (water, shampoo, sauces).

Cartoning Machines – Inserts products into pre-folded boxes (e.g., cereal, medicine).

Vacuum & Gas Flush Sealers – For fresh food to extend shelf life.

Automation & Control

Packing Machines Explained And How To Choose The Right One

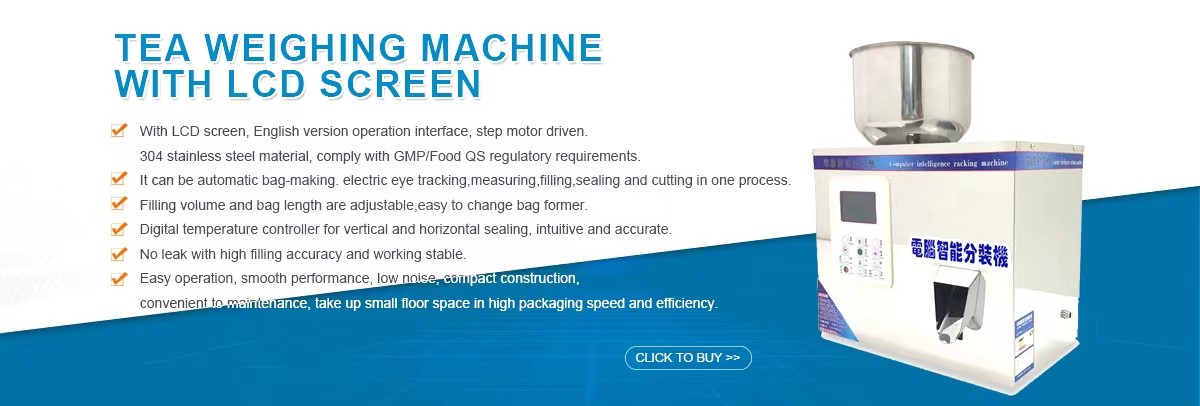

Packing machines automate the process of packaging products, offering efficiency, consistency, and cost savings for businesses. With various types available, selecting the right one depends on multiple factors. Here's a comprehensive guide:

Types of Packing Machines

1. Filling Machines

Liquid fillers: For beverages, oils, cosmetics

Powder fillers: For flour, spices, pharmaceuticals

Granule fillers: For nuts, grains, hardware items

2. Sealing Machines

Heat sealers: For plastic bags and pouches

Induction sealers: For container lids

Vacuum sealers: For food preservation

3. Wrapping Machines

Flow wrappers: For candy bars, snacks

Shrink wrappers: For boxes, multi-packs

Stretch wrappers: For pallet loads

4. Labeling Machines

Pressure-sensitive labelers

Sleeve labelers

Print-and-apply systems

5. Cartoning Machines

Vertical cartoners: For cereal boxes, pharmaceuticals

Horizontal cartoners: For larger items

How to Choose the Right Packing Machine

1. Product Characteristics

Size, shape, and weight

Fragility (requires gentle handling)

Physical state (liquid, powder, solid)

2. Production Requirements

Output speed (units per minute/hour)

Batch size (small vs. large production runs)

Future scalability needs

3. Packaging Materials

Type of material (plastic, glass, metal)

What is Liquid Filling Packaging Machine ?

A liquid filling packaging machine is an automated device that fills liquid products into containers such as bottles, barrels, or bags according to a set quantity, and is widely used in industries such as food and beverage, daily chemicals, pharmaceuticals, and chemicals. Here is a detailed introduction:

Working Principle

Liquid Conveyance: Liquid is transported from the storage tank to the filling valve through pumping, gravity, or air pressure.

Container Positioning: The container is accurately positioned below the filling port by a cylinder or servo motor system.

Automatic Measuring and Filling: According to the filling method (such as time - controlled, flow - meter - based, or weighing - based), the valve is controlled to open and fill according to the set parameters.

Automatic Stop and Anti - Dripping: After filling is completed, the valve closes automatically, and an anti - dripping design prevents liquid residue.

Main Classification

By Filling Principle:

Atmospheric Pressure Filling Machine: Fills by the gravity of the liquid under atmospheric pressure, suitable for low - viscosity, gas - free liquids such as milk.

Pressure Filling Machine: Fills under pressure higher than atmospheric pressure, including equal - pressure filling and pressure - differential filling, suitable for gas - containing liquids such as beer.

Vacuum Filling Machine: Fills under pressure lower than atmospheric pressure, with a simple structure and a wide range of viscosity adaptability, suitable for oils and syrups.

By Operation Type: It can be divided into fully automatic liquid filling machines and semi - automatic liquid filling machines. The former has a high degree of automation and can complete a series of processes such as container conveying, filling, and capping; the latter requires manual assistance for some operations.

By Filling Material: It can be divided into conventional liquid filling machines for low - viscosity liquids such as water, viscous liquid filling machines for high - viscosity liquids such as honey, corrosive liquid filling machines for chemicals such as disinfectants, and sterile liquid filling machines for pharmaceuticals and other high - hygiene - requirement fields.

Structural Composition

It usually includes a liquid delivery system, a filling control system, a metering device, a container positioning system, and an intelligent operation platform. Some advanced filling machines are also equipped with functions such as capping, labeling, and coding.

Advantages

High - efficiency Production: The automatic filling cycle is fast, which can greatly reduce manual operation time and is suitable for large - batch continuous production.

Accurate Dosing: Equipped with a high - precision metering device, the filling error can be controlled within ±0.5%.

Strong Compatibility: It supports a variety of bottle shapes, capacities, and material containers, and the specification switching operation is convenient.

Simple Operation: Adopting a PLC + touch - screen operation interface, parameter adjustment is intuitive, and employees can easily learn and get started.

Application Fields

In the food and beverage industry, it is used for filling mineral water, juice, oil, etc.; in the daily chemical industry, it is used for filling laundry liquid, shower gel, etc.; in the pharmaceutical industry, it is used for filling oral liquids, syrups, etc.; in the chemical industry, it is used for filling lubricating oil, paint, etc.

Equipment Examples

双头全自动活塞式液体灌装机: As shown in the following figure, it has two synchronous filling heads, which can quickly and accurately fill high - viscosity fluids. The parts in contact with materials are made of 316L stainless steel, and it has functions such as anti - dripping and counting.

How Packaging Labeling Machine works !

A Packaging Labeling Machine is a device designed to automatically apply labels (adhesive, pressure-sensitive, or other types) to various packaging surfaces, such as bottles, boxes, cans, jars, or pouches. Its operation combines mechanical precision, sensor technology, and control systems to ensure labels are applied accurately, consistently, and efficiently. Below is a detailed breakdown of how it works:

Core Components

Before diving into the process, it’s helpful to know the key parts that enable labeling:

Label supply system: Holds the label roll (usually a roll of labels on a backing sheet, called liner).

Label separation mechanism: Peels labels from their liner (for pressure-sensitive labels).

Conveyor belt: Transports packages through the machine to the labeling station.

Sensors: Detect the presence, position, or size of packages to trigger labeling.

Application mechanism: Applies the label to the package (e.g., brushes, rollers, or blowers).

Control panel/PLC: Allows operators to adjust settings (label position, speed, etc.) and monitors the process.

Step-by-Step Working Process

The exact workflow may vary slightly based on the machine type (e.g., for flat surfaces, cylindrical bottles, or irregular shapes), but the general steps are:

Package Conveyance

Packages (e.g., bottles, boxes) are fed into the machine via a conveyor belt. The belt speed is synchronized with other components to ensure smooth movement.

Guides or adjustable rails on the conveyor align the packages, keeping them centered or positioned uniformly to prevent misalignment during labeling.

Detection & Synchronization

Sensors (e.g., photoelectric or ultrasonic sensors) detect the arrival of a package at the labeling station. They send a signal to the machine’s control system (PLC) to trigger the labeling process.

The control system calculates the package’s speed and position to ensure the label is applied at the exact right moment (synchronization between conveyor speed and label feeding).

Label Feeding & Separation

For pressure-sensitive labels (the most common type), the label roll rotates, feeding the liner (backing sheet) through a series of rollers.

A peel plate (a sharp, angled edge) causes the liner to bend sharply, separating the label from the liner. The label is now ready to be applied, while the liner is wound onto a take-up roll for disposal or recycling.

For non-adhesive labels (e.g., heat-seal labels), the machine may use heat or pressure to attach the label directly without a liner.

Label Application

The separated label is transferred to the package using one of several methods, depending on the package shape and label type:

Roller application: A rubber roller presses the label onto the moving package, ensuring full contact (ideal for flat or slightly curved surfaces).

Brush application: Soft brushes push the label onto irregular or fragile surfaces (e.g., glass jars with ridges).

Blower application: Compressed air blows the label onto the package (used for lightweight labels or hard-to-reach areas).

Vacuum application: A vacuum pad picks up the label and places it precisely (common for large or heavy labels).

Label Smoothing (Optional)

Some machines include a secondary roller or brush to smooth the label, removing air bubbles and ensuring it adheres firmly to the package surface.

Quality Checks (Optional)

Advanced machines may integrate cameras or sensors to inspect labels for:

Correct position (e.g., not crooked or overlapping).

Presence (no missing labels).

Print quality (e.g., barcode readability).

Defective packages can be automatically rejected from the conveyor.

Finished Product Output

Labeled packages continue along the conveyor to the next stage of production (e.g., cartoning, palletizing, or shipping).

Key Variations by Application

Cylindrical labeling machines: For round containers (e.g., bottles, cans), using rollers to wrap labels around the curved surface.

Flat surface labeling machines: For boxes, pouches, or square containers.

Wrap-around labeling machines: Apply a single label that wraps entirely around a container (common for beverage bottles).

Top/bottom labeling machines: Apply labels to the top or bottom of packages (e.g., boxes of electronics).

Advantages

Speed and efficiency: Handles hundreds to thousands of packages per hour, far faster than manual labeling.

Accuracy: Ensures labels are positioned consistently (critical for branding, regulatory compliance, and barcode scanning).

Flexibility: Easily adjustable for different label sizes, package shapes, and production speeds via the control panel.

Reduced waste: Minimizes label misalignment or damage compared to manual methods.

In short, packaging labeling machines streamline the process of applying labels, ensuring precision, speed, and reliability—essential for mass production in industries like food and beverage, pharmaceuticals, cosmetics, and logistics.

What is Electric liquid filling and packaging machine ?

An Electric liquid filling and packaging machine is an automated piece of equipment powered by electricity, designed to efficiently fill liquid products into containers (such as bottles, cans, or pouches) and complete subsequent packaging processes. It is widely used in industries like food and beverage, pharmaceuticals, cosmetics, and chemicals, streamlining the production of liquid-based goods.

Key Functions and Working Process

The machine integrates multiple steps to transform empty containers into fully packaged products. A typical workflow includes:

Container Conveyance: Empty containers are transported to the filling station via a conveyor belt.

Positioning and Fixing: Mechanical devices align and secure containers to prevent displacement during filling.

Liquid Filling: Liquids are dispensed into containers in precise, pre-set volumes (e.g., milliliters, liters). Filling methods vary based on liquid viscosity (e.g., water, syrup, oil) and include:

Gravity filling (for low-viscosity liquids).

Pressure filling (for foamy or volatile liquids).

Vacuum filling (for thick or viscous liquids).

Residue Removal: Some machines clean excess liquid from container mouths to avoid interfering with sealing.

Sealing/Capping: Containers are sealed using methods like screw capping, press capping, or heat sealing (for pouches) to prevent leakage or spoilage.

Labeling and Coding (Optional): Labels (with branding, ingredients, or expiration dates) are applied, and production details (e.g., batch numbers) are printed.

Finished Product Handling: Packaged products are conveyed to the next stage (e.g., cartoning, storage).

Key Features

High Automation: Reduces manual labor, boosts production speed, and minimizes human errors (e.g., inaccurate filling volumes).

Adjustability: Parameters like filling volume and speed can be easily modified via control systems (e.g., PLC programming) to accommodate different container sizes and liquid types.

Hygiene and Safety: Parts in contact with liquids are often made of food-grade or pharmaceutical-grade materials (e.g., stainless steel), ensuring compliance with industry standards (e.g., FDA for food, GMP for pharmaceuticals) and ease of cleaning.

Versatility: Handles liquids of varying viscosities, corrosiveness, or volatility—from low-viscosity liquids (water, juice) to high-viscosity ones (honey, sauces), and even some particle-containing liquids (with specialized filling nozzles).

Applications

Food & Beverage: Bottled water, juice, soy sauce, vinegar, cooking oil, sauces.

Pharmaceuticals: Oral liquids, disinfectants, medical alcohol, pharmaceuticals.

Cosmetics & Daily Chemicals: Shampoo, laundry detergent, skincare products, cleaning agents.

Chemicals: Small-packaged lubricants, antifreeze, coatings.

our newest static inkjet printer

News:our newest static inkjet printer

static inkjet printer compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market. summarizes the defects of past products, and continuously improves them. The specifications of static inkjet printer can be customized according to your needs..

The product is earth-friendly, low energy, and long-lasting, helping users save energy, replacement costs as well as cut electricity demand.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!